From what Mark is saying about how yeast is genetically modified to stay in *suspension* until the wort dips below a threshold level of sugar

The tendency to remain in suspension until genetically set levels of glucose, mannose, maltose, sucrose, and maltriose are reached is only exhibited by yeast strains that exhibit NewFlo flocculation. The are Flo1 brewing strains where flocculation is inhibited by mannose, but not glucose. NCYC 1269 is a Saccharomyces pastorianus (lager) strain that exhibits Flo1 flocculation.

NCYC 1269

Information

Flocculent.

Flo1 type flocculation.

For use in Tower Continuous Fermenters.

Depositor

Dr. R.N. Greenshields, University of Aston, Birmingham, UK.

Deposit Name

Saccharomyces cerevisiae, Saccharomyces carlsbergensis, Sacc

Month of deposit

March

Deposit Year

1968

Habitat

Lager production strain.

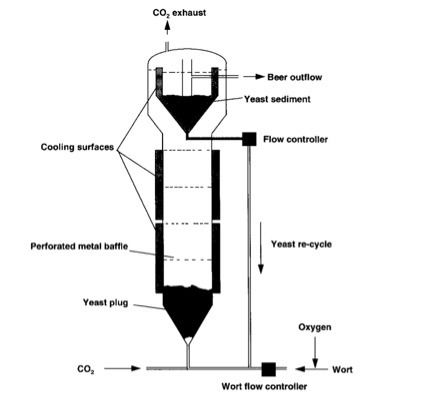

Hopefully, forum members noticed the comment about the NCYC 1269 being used in continuous tower fermentation. Continuous fermentation is a very different process from how we make beer. Tower fermenters are bioreactors that are used to ferment beer using a continuous process where beer is continuously drawn off of the top while fresh wort and O

2 are added, and yeast is recycled. Fermentation occurs very quickly in a tower fermentation vessel. Ales usually ferment in around 4 hours whereas lagers ferment in around 10 hours. While exhibiting NewFlo flocculation, Whitbread "B" (a.k.a. NCYC 1026, Wyeast 1098, White Labs WLP007, and Fermentis S-04) was originally selected for use in tower fermentation vessels, which is why it is so darn flocculent.

NCYC 1026

Information

Flocculent.

NewFlo type flocculation.

1:5:4:5:5

O2, DMS 33 µg/l, low acetic, high lactic, diacetyl 0.42ppm only,

used commercially in Tower

Fermenters (continuous process), non head-forming, no estery flavour. Contains 2µ plasmid.

Depositor

British Brewery

Deposit Name

Saccharomyces cerevisiae

Month of deposit

June

Deposit Year

1958

Habitat

Ale production strain

Tower Fermentation Vessel