This build is still a work in progress, but I figured I that I would post the photos that I have shot thus far.

For those who have ever wondered how clean non-round holes are made, well, in the absence of a CNC machining center, one uses an old-fashioned router, a routing template, and a flush trim bit (bearing on the bottom) or a pattern bit (bearing on the top). A plunge router can be used to cut the hole. However, I usually cut a hole that is slightly undersize with my sabre saw and use my router to trim the hole flush with the pattern. I used the base that came with the mill as my routing pattern. The material being routed is called seaboard. It is a UV stable high-density polyethylene (HDPE) sheet material that is used in the marine industry. HDPE is quite dense, so there should be very little vibration after assembly has been completed.

As one can see in this photograph, my 1" flush trim bit has a larger radius than the bit that was used to cut the original base.

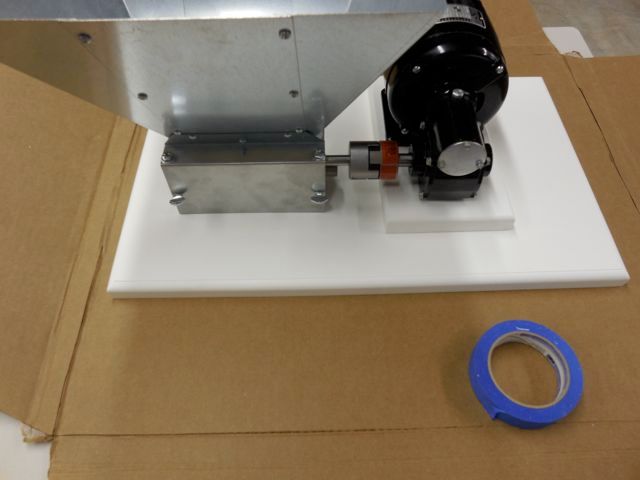

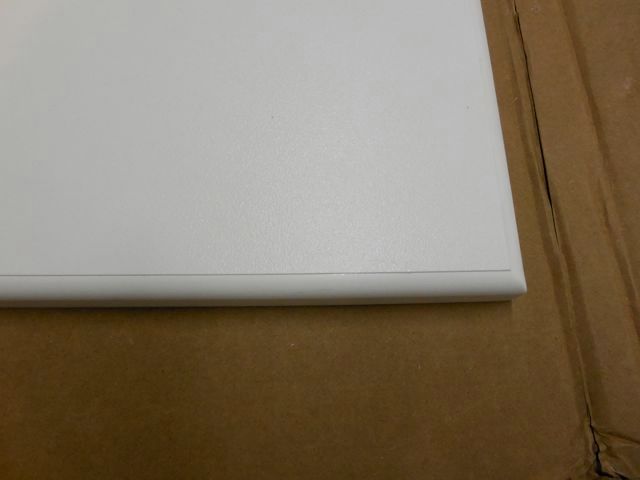

Here's the main table and the shim that I cut for the Bodine gear motor that I purchased for this build. The Bodine gear motor had to be raised exactly one inch to mate up with the MM3. The top edge on the motor shim was rounded over with a 1/4" radius round-over bit that was set to cut shallow. The top edge of the main table was rounded-over using a 3/8" radius round-over bit that was set such that the top the radius was slightly below the face of the sheet. I have not done any of this kind of work with a hand-held router in a long time. My router used to be mounted in a routing table. Doing this kind of work with routing table is much easier.

I also used the original base as my drilling template. My floor drill press is the only piece of machinery that I still own from my foray into woodworking. I do not use it very often, but there are times when the precision of a drill press is needed.

The effect created by setting the router bit such that the top of the radius is slightly below the face of the sheet is easier to see in this photograph.

Here are a few photos of the Bodine gear motor and the Mill just resting on top of the base.