My grain mill began as a practice project to hone my welding skills before I tackled my brew stand and pots. This was back in 2007, two years after I began homebrewing with extract. With no prior welding experience, I bought myself a TIG welder, picked up some mild steel tubing and went at it. I did practice a little bit to find the right settings on the welder and to develop my technique some.

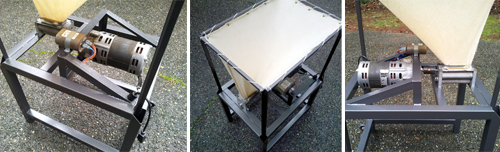

I chose to use a Crankandstien 3 roller mill and picked up a used gear-head Bodine motor from a surplus store. The motor is rated at 100 lb. in. of torque and rotates at 151 RPM. I designed the mill to fit over a large Tupperware tub. To be honest, at this point, I did not know how I was going to build the hopper, but I knew I wanted it to be large enough to hold enough grain for a high gravity 10 gallon batch. Many of the mills I saw on the internet built by other homebrewers were either driven by a hand crank or a drill, many of which also had very small hoppers. A large hopper was a must for me, as was the ability to flip a switch and walk away while it did its thing. The truth, however, is that I always sit and watch the grain being milled. Its just too cool to walk away from. I guess there is a certain satisfaction that comes over me when I sit and watch it.

I was anxious to run some grain through it. It was only after I welded in the uprights and made a temporary cardboard hopper did I get the idea to make the hopper out of heavy canvas. I had essentially already created the template and I thought it would be easy enough to transfer that to the canvas. I have never seen any other hopper built this way. I think the canvas gives the mill a certain character that sets it apart. Sort of reminiscent of old farm equipment.

Fast forward about 5+ years. I recently moved from southern California to the pacific northwest. Go figure, the WA climate immediately changed my dull gray steel frame to a nice rust colored orange. I had always meant to have the frame powdercoated, and I figured this was the perfect opportunity. I also added two caster wheels to the back side of the rear legs. Tip the mill back and you can wheel it around, lean it forward and remains stable and stationary. This was a great addition. You can see the final product. I am very happy with the results.

Share Post