I brew like a simple pot on a stove. Because I think it is important to brew in a reproducible way I use automation to achieve this. Actually I use a predecessor of Tcontrol to control all the mash steps temperatures and timings. All the brewing is done without a pump. The inside of the kettle is RVS the outside is iron.

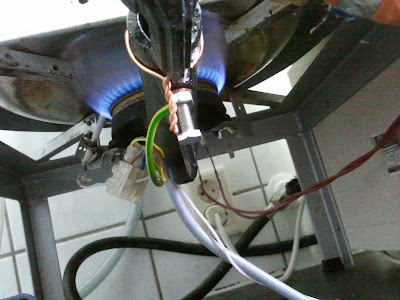

Mash tun with stirring motor on top and direct heater which is controlled by a proportional valve from a central gas heater. A handmade PCB with some I2C components is the interface to the parallel port of the brewing PC.

The stirrer used in the kettle is driven by 24 Vdc which is speed controlled by the PC depending on the heating in the last minutes.

On the brewing PC I fill in the mash scheme for this beer.

The home made brewing program is called BeerPID. The program BeerPID is not a PID controller anymore but uses a feedback an feed forward analog algorithm. Digital temperature sensors measure the temperature of the wort.

This photo shows the bottom side of the mash tun during heating. Also the wiring of the electrical ignition and the flame monitoring sensor can be seen.

After mashing the mash tum is hoisted on the counter with a electrical cable hoist.

The heating of the sparge water is automatically started after the mashing and regulated to 82 degrees Celsius during the sparge.

The sparge water bucket is about 25 liter. It contains a chip fryer heating element mounted 4 cm above the bottem into the water.

After filtering and sparging the boiling starts.

The software detects the start of the boiling so the first hop can be added. A timer on the screen is used to give alarm when next hop or sugar should be added.