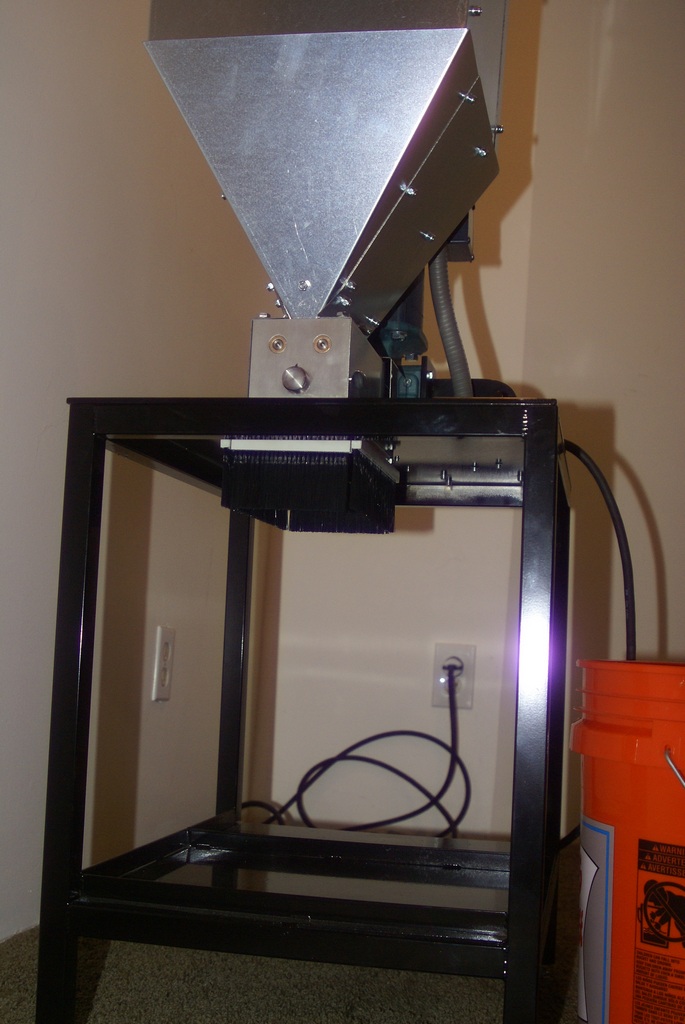

Just finished our new grain mill. Using a Monster Mill 3 with the stainless rollers and 1/2 drive shaft upgrade. I have the hopper extensions for our large 10 gallon batch grain bills. I'm driving it with a 1/2 hp 1725 RPM 115v motor through a 10:1 Dodge/Reliance Tigear 56/133-10 gearbox directly coupled to the input shaft using a Lovejoy spider coupling all purchased on ebay. Fabricated a nice handled cover to keep crud out when not in use.

The bucket shelf has a guide to center the Homer Bucket under the bottom of the mill. I used some H bracket brushes that I picked up from Grainger to guide the milled grain into the bucket. The frame is fabricated from TIG welded 1" square tubing. The upper shelf is 3/16 carbon steel and the bucket shelf is 11ga CS.

Wasn't really sure if 172.5 RPM was going to be enough but we are very pleased with how quickly the mill can crack open our grain mix. Plenty of power to fill the hopper and flick on the switch without a whimper.